-

09.30 – Dr. Bernd Wiegand, Peter PutschOpening & Welcome

09.30 – Dr. Bernd Wiegand, Peter PutschOpening & Welcome -

09.30 – Udo Mühlbauer, Uhde Inventa-Fischer GmbH/thyssenkrupp, BerlinThe bioplastics market and technologies for their production

09.30 – Udo Mühlbauer, Uhde Inventa-Fischer GmbH/thyssenkrupp, BerlinThe bioplastics market and technologies for their productionUdo Mühlbauer, PLA Pilot Plant Manager Uhde Inventa-Fischer GmbH/thyssenkrupp, Berlin

-

10.15 – Ing. Daniel Schönleitner, FDU Hotrunner GmbH, Nußbach (Austria)Flat Die Unit – Düsensystem für schonende Verarbeitung im Spritzguss

10.15 – Ing. Daniel Schönleitner, FDU Hotrunner GmbH, Nußbach (Austria)Flat Die Unit – Düsensystem für schonende Verarbeitung im SpritzgussIng. Daniel Schönleitner, Projektmanagement FDU, FDU Hotrunner GmbH, Nußbach (Austria)

-

11.15 – Andre Rapthel, BYK Additives & Instruments, Unit SchkopauModifier for viscosity regulation and melt strength improvement in PLA Compounds

11.15 – Andre Rapthel, BYK Additives & Instruments, Unit SchkopauModifier for viscosity regulation and melt strength improvement in PLA CompoundsAndre Rapthel, Head of Application Development Plastics BYK Additives & Instruments, Unit Schkopau

-

11.45 – Dr.-Ing. Kristin Riedel, Folienwerk Wolfen GmbH, Bitterfeld-Wolfen„Vom Korn zum Blister“ – Herstellungsprozess nachhaltiger Verpackungen aus PLA

11.45 – Dr.-Ing. Kristin Riedel, Folienwerk Wolfen GmbH, Bitterfeld-Wolfen„Vom Korn zum Blister“ – Herstellungsprozess nachhaltiger Verpackungen aus PLADr.-Ing. Kristin Riedel, Research & Development Folienwerk Wolfen GmbH, Bitterfeld-Wolfen

-

14.30 – Joerg Kohl, BASF SE, LudwigshafenFrom the beginnings to multi-cavity moulds with In-Mold Label (IML).

14.30 – Joerg Kohl, BASF SE, LudwigshafenFrom the beginnings to multi-cavity moulds with In-Mold Label (IML).Joerg Kohl, Technical Marketing Biopolymers BASF SE, Ludwigshafen

abstract and contact information…

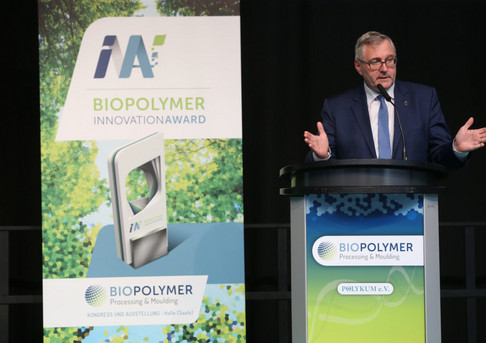

Dr. Jürgen Ude, States Secretary in the Ministry of Economic Affairs, Science and Digitalization of Sachsen-Anhalt, recognizes the BIOPOLYMER Innovation Award as a major initiative for the further development of the plastics industry., (photo: © Uwe Köhn)

Dr. Jürgen Ude, States Secretary in the Ministry of Economic Affairs, Science and Digitalization of Sachsen-Anhalt, recognizes the BIOPOLYMER Innovation Award as a major initiative for the further development of the plastics industry., (photo: © Uwe Köhn)

The Laudators Dr. Martin Bussmann (BASF SE, l.) and Michael Walter (Omya GmbH, r.) presented the winners and explained the decisions of the jury., (photo: © Uwe Köhn)

The Laudators Dr. Martin Bussmann (BASF SE, l.) and Michael Walter (Omya GmbH, r.) presented the winners and explained the decisions of the jury., (photo: © Uwe Köhn)

The Laudators Dr. Martin Bussmann (BASF SE, l.) and Michael Walter (Omya GmbH, r.) presented the winners and explained the decisions of the jury., (photo: © Uwe Köhn)

The Laudators Dr. Martin Bussmann (BASF SE, l.) and Michael Walter (Omya GmbH, r.) presented the winners and explained the decisions of the jury., (photo: © Uwe Köhn)

The Laudators Dr. Martin Bussmann (BASF SE, l.) and Michael Walter (Omya GmbH, r.) presented the winners and explained the decisions of the jury., (photo: © Uwe Köhn)

The Laudators Dr. Martin Bussmann (BASF SE, l.) and Michael Walter (Omya GmbH, r.) presented the winners and explained the decisions of the jury., (photo: © Uwe Köhn)

Mika Hurri, Sales Manager of Arctic Biomaterials, Tampere (r.), received the award from States Secretary Dr. Jürgen Ude. The finish company was awarded for the pathbreaking biocomposites „ArcBiox“ with degradable glass fibre., (photo: © Uwe Köhn)

Mika Hurri, Sales Manager of Arctic Biomaterials, Tampere (r.), received the award from States Secretary Dr. Jürgen Ude. The finish company was awarded for the pathbreaking biocomposites „ArcBiox“ with degradable glass fibre., (photo: © Uwe Köhn)

Congratulations to Anselm Gröning (m.), General Manager of Nölle Kunststofftechnik GmbH, for the 2nd Prize by Peter Putsch, Chairman of POLYKUM e.V. (l.), and states secretary Dr. Jürgen Ude (r.). Nölle Kunststofftechnik was awarded for its „re+casts®“, a medical cast system for the treatment of bone fractures. The casts can be readjusted during the healing process and composted after the use., (photo: © Uwe Köhn)

Congratulations to Anselm Gröning (m.), General Manager of Nölle Kunststofftechnik GmbH, for the 2nd Prize by Peter Putsch, Chairman of POLYKUM e.V. (l.), and states secretary Dr. Jürgen Ude (r.). Nölle Kunststofftechnik was awarded for its „re+casts®“, a medical cast system for the treatment of bone fractures. The casts can be readjusted during the healing process and composted after the use., (photo: © Uwe Köhn)

The 1st Prize with the 2.000 Euro winner’s cheque went to Christoph Glammert, CEO of the Biofibre GmbH (m) in Altdorf. Dr. Jürgen Ude, States Secretary (r.) and Peter Putsch, Chairman of POLYKUM, granted the prize with warm congratulations. The prize awards the creation of a new biodegredable granulate for the storage and transportation of paving slabs with an impressive environmental impact., (photo: © Uwe Köhn)

The 1st Prize with the 2.000 Euro winner’s cheque went to Christoph Glammert, CEO of the Biofibre GmbH (m) in Altdorf. Dr. Jürgen Ude, States Secretary (r.) and Peter Putsch, Chairman of POLYKUM, granted the prize with warm congratulations. The prize awards the creation of a new biodegredable granulate for the storage and transportation of paving slabs with an impressive environmental impact., (photo: © Uwe Köhn)

The 1st Prize with the 2.000 Euro winner’s cheque went to Christoph Glammert, CEO of the Biofibre GmbH (m) in Altdorf. Dr. Jürgen Ude, States Secretary (r.) and Peter Putsch, Chairman of POLYKUM, granted the prize with warm congratulations. The prize awards the creation of a new biodegredable granulate for the storage and transportation of paving slabs with an impressive environmental impact., (photo: © Uwe Köhn)

The 1st Prize with the 2.000 Euro winner’s cheque went to Christoph Glammert, CEO of the Biofibre GmbH (m) in Altdorf. Dr. Jürgen Ude, States Secretary (r.) and Peter Putsch, Chairman of POLYKUM, granted the prize with warm congratulations. The prize awards the creation of a new biodegredable granulate for the storage and transportation of paving slabs with an impressive environmental impact., (photo: © Uwe Köhn)

-

15.00 – Dr. Thomas Günther, Eurofins Umwelt Ost GmbH, JenaMethods, standards and specifications for biodegradability and compostability testing of bioplastic materials

15.00 – Dr. Thomas Günther, Eurofins Umwelt Ost GmbH, JenaMethods, standards and specifications for biodegradability and compostability testing of bioplastic materialsDr. Thomas Günther, Laboratory Manager Eurofins Umwelt Ost GmbH, Jena

-

16.15 – Florian Dresel, HEXPOL TPE GmbH, LichtenfelsSoft sustainable plastics with biobased and cork-filled TPEs

16.15 – Florian Dresel, HEXPOL TPE GmbH, LichtenfelsSoft sustainable plastics with biobased and cork-filled TPEsFlorian Dresel, Central Research Engineer HEXPOL TPE GmbH, Lichtenfels

-

16.45 – Marco Siekmann, digicolor GmbH, HerfordBio-Drying: Materialgerechte Trocknungsprozesse für Biokunststoffe

16.45 – Marco Siekmann, digicolor GmbH, HerfordBio-Drying: Materialgerechte Trocknungsprozesse für BiokunststoffeMarco Siekmann, Managing director digicolor GmbH, Herford

-

12.15 – Award CeremonyVerleihung: BIOPOLYMER Innovation Award

12.15 – Award CeremonyVerleihung: BIOPOLYMER Innovation Award