Whether it's about making car headlights more resistant to scratches, giving hygienic surfaces an antibacterial finish or reliably shielding plastic components against electromagnetic waves: the 110 employees at Techniplas Schwäbisch Gmünd GmbH have suitable technical solutions for almost every design requirement. The unique machinery and the inspiring creativity that the coating professionals develop for their customers on a total of 10,000 square meters of production space are in demand by automobile manufacturers as well as in the medical industry, by electrical and household appliance manufacturers as well as by aircraft manufacturers and watch manufacturers. “On request, as part of the Techniplas Group, we can of course also offer the entire value chain from plastic injection molding to surface finishing,” emphasizes sales manager Norbert Weiss.

“With the SICRALAN® product family, scratch-resistant, reflex-reducing and, if desired, chemical-resistant surfaces can be applied to plastic components using transparent coatings, for example,” explains the authorized representative. In addition to a variety of conventional coating processes, Techniplas, for example, has “a globally unique inkjet technology with which, in contrast to conventional painting technology, components can be coated without masking technology and selectively according to customer specifications.” The process allows use on transparent and non-transparent plastics. High-gloss black products with a scratch-resistant surface produced using the inkjet process are particularly in demand in the premium sector of the automotive industry.

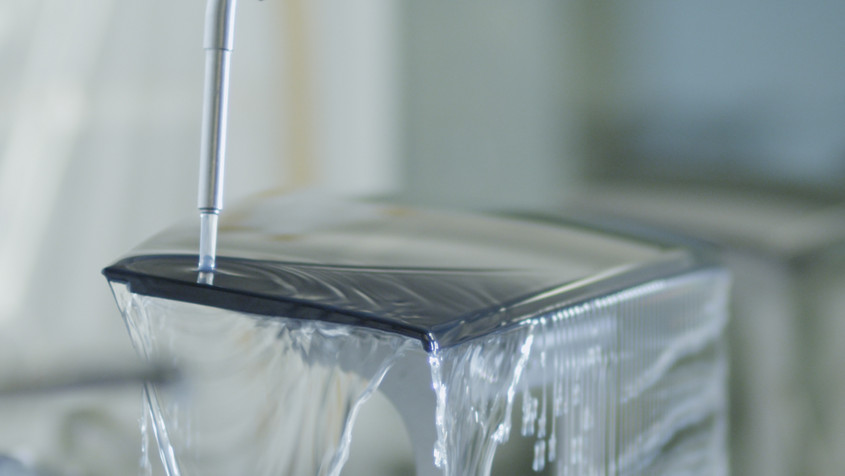

Another technical highlight of the company is the electromagnetic shielding of electronics housings using the patented ELAMET® process. “Metals such as aluminum, copper, steel or gold are deposited on plastic surfaces in the micrometer range in high-vacuum vapor deposition systems,” explains Weiss. The metal layer created in this way forms “a closed, electrically conductive surface that can achieve effective shielding that plastic components normally lack.”

Founded in 1977 as a subsidiary of Degussa AG in Schwäbisch Gmünd, the company earned an excellent reputation among customers all over the world as independent "GfO - Company for Surface Technology" from 1993 to 2010. In August 2010 it was taken over by Nanogate AG. The research and production facility in Schwäbisch Gmünd has been part of the global Techniplas Group since 2021.

On the one hand, Weiss expects new development partnerships and other collaborations from the now sealed membership in POLYKUM e.V.: “We got to know POLYKUM at several internationally renowned trade fairs. Through conversations with members, the feeling arose: We fit into this plastics community in which medium-sized companies and top-class research institutions have come together - and it suits us." Techniplas is represented for the first time at the POLYKUM e.V. joint stand at the KPA trade fair in Ulm.